Glas und Glastechnologie

Publikationen Glas und Glastechnologie

2025

- Sasaki S., Munakata, S., Takahashi, E., Masuno, A., Deubener, J.

Crystallisation of levitated TeO2 glass

Acta Materialia 304 (2026) 121784, ISSN 1359-6454,

doi.org/10.1016/j.actamat.2025.121784

(https://www.sciencedirect.com/science/article/pii/S1359645425010717)

Abstract

The non-isothermal crystallisation of levitated TeO2 glass beads was studied by thermal analysis and Raman spectroscopy. It was found that metastable γ-TeO2, whose structure is closest to that of glass, already nucleates in the bulk at the onset of the glass transition region. On the surface, heterogeneous crystal nucleation resulted to immediate growth of the thermodynamic stable α-TeO2. This led to a scenario in which a crystallised layer of α-TeO2 grew from the surface inwards and encountered growing γ-TeO2 crystallites in the interior, which were transformed by the contact. By simulating the non-isothermal crystallisation, the share of heat that was due to this transformation could be determined and initial data on the growth and nucleation rates of the corresponding crystalline polymorphs in pure TeO2 glasses were obtained.

- Streichert, J., Meyer, S., Zandonà, A., Di Genova, D., Deubener, J.

Precipitation Kinetics of Nucleating Agents in LAS Glass-Ceramics by High Temperature Raman Spectroscopy

Glass Europe (2025), 3, 203–219

doi.org/10.52825/glass-europe.v3i.2742

(https://www.tib-op.org/ojs/index.php/glass-europe/article/view/2742)

Abstract

The precipitation kinetics of nucleating agents in technical lithium aluminosilicate (LAS) glass-ceramics is challenging to determine in laboratory practice due to the low content of about 3 wt%. Therefore, isothermal heat treatment series in the temperature range 750–820 °C with simultaneous recording of Raman spectra were carried out, which revealed a two-fold crystallisation process. In the first stage, an increase in oxygen coordination of Ti4+ from 4 and 5 to 6 is indicated, which was assigned to a liquid-liquid phase separation, while in the second stage ordering of the short range led to crystallisation of TiO2(B) and anatase in the demixed domains. Using a sectional JMAK analysis of the temporally decoupled process, a stationary nucleation mechanism with no detectable growth is proposed for the first stage, while the second stage led to almost no change in volume fraction over time.

- Di Genova, D., Giuliani, G., Abeykoon, S., Dadwal, K., Sharma, S., Khanna, A., Zandonà, A., Bondar, D., Meyer, S., Calabrò, L., Dominijanni, S., Deubener, J.

Intralaboratory calibration of the DSC shift-factor approach for melt viscosity determination: A case study on lead metasilicate glass

Journal of Non-Crystalline Solids 666 (2025) 123709

doi.org/10.1016/j.jnoncrysol.2025.123709

(https://www.sciencedirect.com/science/article/pii/S0022309325003254)

Abstract

The differential scanning calorimetry (DSC) shift-factor approach provides a powerful tool for determining the shear viscosity of glass-forming melts across several orders of magnitude. Its accuracy, however, depends on the proper determination of the shift factor (K) – a process of establishing K by linking DSC data to viscometry, herein termed ’intralaboratory calibration’ – which then connects the fictive temperature to viscosity. In this study, we determine K for lead metasilicate (PbSiO3) glass by integrating conventional DSC, flash DSC, and ball penetration viscometry measurements on samples obtained from the same batch. Raman spectroscopy was employed to verify sample integrity before and after measurements. Our results confirm the applicability of the DSC shift-factor approach, yielding shift factors of Konset = 10.92 ± 0.04, Kpeak = 9.41 ± 0.08, and Kendset = 8.71 ± 0.07. These findings underscore the importance of intralaboratory calibration in refining the DSC-based method for accurate viscosity determination in glass-forming systems.

- Pan, Z., Waurischk, T., Duval, A., Müller, R., Deubener, J., Krishnan, N.M.A., Wondraczek, K., Wondraczek, L.

Precise real-time measurement of liquid viscosity using digital video data

Advanced Intelligent Systems (2025), 2500297, ISSN 2640-4567

doi.org/10.1002/aisy.202500297

(https://advanced.onlinelibrary.wiley.com/doi/10.1002/aisy.202500297)

Abstract

Quantitative knowledge of liquid viscosity is of fundamental importance in many areas of materials synthesis and processing. However, the determination of viscosity often relies on specialized experimental equipment, offline experimentation, or invasive procedures, in particular when required in extreme conditions such as at high temperature, high pressure, and in confined or corrosive environments. Here, this study proposes and validates a fast and simple method that mimics the intuitive perception of liquid flow within a quantitative framework. For this, this study employs digital video observation to derive quantitative values of the shear viscosity of liquids, with high precision and rapid acquisition rates. The technique involves capturing liquid dynamics after minor mechanical stimulation. Processed imaging data are indexed by similarity and referenced to a digital database generated with a finite element model, from which values of viscosity are obtained in line. The approach is tested on water at room temperature and on a high-temperature glass melt. Covering a viscosity range of four orders of magnitude, both yield convincing agreement with tabulated reference data at low computational cost.

- Valdivia, P., Zandonà, A., Löschmann, J., Bondar, D., Genevois, C., Canizarès, A., Allix, M., Miyajima, N., Kurnosov, A., Ballaran, T. B., Di Fiore, F., Vona, A., Romano, C., Deubener, J., Bamber, E. C., Longo, A., Di Genova, D.

Nanoscale chemical heterogeneities control the viscosity of andesitic magmas

Communications Earth & Environment (2025), 6, 455, ISSN 2662-4435

doi.org/10.1038/s43247-025-02424-9

(https://www.nature.com/articles/s43247-025-02424-9)

Abstract

Explosive volcanic eruptions, driven by magma fragmentation, pose significant geohazards due to their rapid energy release and widespread dispersal of pyroclasts. High magma viscosity promotes brittle fragmentation by limiting volatile escape and enhancing internal pressure buildup. Although recent studies have recognized that iron-titanium oxide nanocrystal formation increases melt viscosity, the mechanisms underlying this effect remain poorly constrained. Here we quantify the influence of nanocrystallization on magma viscosity by developing viscosity models that incorporate iron-titanium variations, calibrated against nanocrystal-free andesitic melts. Using time-resolved imaging, we show that nanocrystals form within seconds within synthetic andesitic melts. This process generates nanoscale chemical heterogeneities, including silica enrichment in the surrounding melt and aluminum-rich shells embedding the nanocrystals. These heterogeneities result in viscosity increases of up to 30-fold at eruptive temperatures. Our findings indicate that nanocrystallization modulates magma rheology during early crystallization, with direct implications for the dynamics of andesitic eruptions.

- Waurischk, T., Deubener, J., Müller, R.

Internal friction and energy dissipation during fracture in silicate glasses

Journal of Chemical Physics (2025), 162 (19): 194709, ISSN 0021-9606

doi.org/10.1063/5.0255432

(https://pubs.aip.org/aip/jcp/article/162/19/194709/3347153/Internal-friction-and-energy-dissipation-during)

Abstract

To obtain a deeper insight into the nature of energy dissipation during fracture, the internal friction of 13 borosilicate, aluminosilicate, soda-lime, and lead-containing glasses, for which inert crack growth data are known, was measured using dynamic mechanical thermal analysis. For asymmetrically bent glass beams, the loss tangent, tan δ, was determined between 0.2 and 50 Hz at temperatures between 273 K and the glass transition temperature, Tg. It was found that the area under the tan δ vs T·Tg−1 curve correlates with the crack growth exponent, n, in the empirical v = v0·KIn relation between crack growth velocity, v, and stress intensity, KI, which indicates that n correlates with the degree of energy dissipation of sub-Tg relaxation phenomena.

- Al-Mukadam, R., Murata, T., Nakane, S., Yamazaki, H., Deubener, J.

Overheating-Dependent Heterogeneous Crystal Nucleation in a Lithium Disilicate Melt

Glass Europe (2025), 3, 77–87

doi.org/10.52825/glass-europe.v3i.2563

(https://www.tib-op.org/ojs/index.php/glass-europe/article/view/2563)

Abstract

The influence of thermal history on the kinetics of liquid-solid transformations is investigated for heterogeneous crystal nucleation near the liquidus temperature in a melt with lithium disilicate composition in contact with a PtRh10 carrier. It is shown that the achieved undercooling depends on the preceding superheating protocol. This is explained by a distribution of nano-sized cavities on the surface of the precious metal, in which crystalline clusters can persist above the liquidus temperature for a characteristic time. In series of different surface quality of the PtRh10 carrier and for air purging, these times are in the range of 5-20 s, which seems relatively long compared to metallic melts, where this phenomenon was first observed in the millisecond range. The high viscosity of the silicate melt at the liquidus temperature is discussed as the reason for the difference in the persistence time.

- Fritzsche, J.-O., Groß, C. B. M., Deubener, J.

Enthalpy of Mixing of Sodium Borosilicate Glasses by DSC Analysis

Glass Europe (2025), 3, 29–42

doi.org/10.52825/glass-europe.v3i.2606

(https://www.tib-op.org/ojs/index.php/glass-europe/article/view/2606)

Abstract

An easy-to-use method to determine the enthalpy of mixing (ΔHmix) from the differential scanning calorimetry (DSC) heating curve of demixed borosilicate glasses of the composition zSiO2 (1-z)(0.16Na2O·0.84B2O3) with z = 0.775, 0.55 and 0.424 is presented. It is shown that ΔHmix results from the area under the endothermic mixing event of the DSC heating curve, but that ΔHmix can also be used to approximate the initial compositions of the boron-rich and silica-rich domains that exhibit the glass transition temperatures Tg1 and Tg2 of the DSC upscans.

- Giordano, G., Pensa, A., Vona, A., Di Genova, D., Al-Mukadam, R., Romano, C., Deubener, J., Frontoni, A., Petrone, P. P.

Unique formation of organic glass from a human brain in the Vesuvius eruption of 79 CE.

Scientific Reports 15, 5955 (2025), ISSN 2045-2322

doi.org/10.1038/s41598-025-88894-5

(https://www.nature.com/articles/s41598-025-88894-5)

Abstract

Glass forms when a liquid is fast cooled preventing crystallization, across a reversible process known as the glass transition. Organic tissues are commonly preserved as glass by processes of vitrification at very low temperatures, known as cryopreservation, and can return to their original soft state when heated back to ambient temperature. It would therefore be impossible to find organic glass embedded in volcanic deposits that have reached several hundred of Celsius degrees. Here we demonstrate that material with glassy appearance found within the skull of a seemingly male human body entombed within the hot pyroclastic flow deposits of the 79 CE Vesuvius eruption formed by a unique process of vitrification of his brain at very high temperature, and is the only such occurrence on Earth. Calorimetric analyses show that the temperature at which the brain transformed into glass was well above 510 °C, implying that the body was exposed to the passage and vanishing of a short-lived, dilute and much hotter pyroclastic flow, explaining its early fast heating and the following very fast cooling. The glass that formed as a result of such a unique process attained a perfect state of preservation of the brain and its microstructures.

- Chen, Y.-F., Arendt, F., Bornhöft, H., de Camargo, A.S.S., Deubener, J., Diegeler, A., Gogula, S., Contreras Jaimes, A.T., Kempf, S., Kilo, M., Limbach, R., Müller, R., Niebergall, R., Pan, Z., Puppe, F., Reinsch, S., Schottner, G., Stier, S., Waurischk, T., Wondraczek, L., Sierka, M.

Ontology-Based Digital Infrastructure for Data-Driven Glass Development

Advanced Engineering Materials (2025) 2401560, ISSN 1438-1656

doi.org/10.1002/adem.202401560

(https://onlinelibrary.wiley.com/doi/10.1002/adem.202401560)

Abstract

The development of new glasses is often hampered by inefficient trial-and-error approaches. The traditional glass manufacturing process is not only time-consuming, but also difficult to reproduce with inevitable variations in process parameters. These challenges are addressed by implementing an ontology-based digital infrastructure coupled with a robotic melting system. This system facilitates high-throughput glass synthesis and ensures the collection of consistent process data. In addition, the digital infrastructure includes machine learning models for predicting glass properties and a tool for extracting patent information. Current glass databases have significant gaps in the relationships between compositions, process parameters, and properties due to inconsistent studies and nonconforming units. In addition, process parameters are often omitted, and even original literature references provide limited information. By continuously expanding the database with consistent, high-quality data, it is aimed to fill these gaps and accelerate the glass development process.

- Da Fonseca BP, Helsch G, Zandonà A, Deubener J.

Crystallographic assessment and thermal expansion fine-tuning of quartz solid solutions in the ZnO–MgO–Al2O3–SiO2 system

Journal of the American Ceramic Society (2025) 108:e20314, ISSN 0002-7820

doi.org/10.1111/jace.20314

(https://ceramics.onlinelibrary.wiley.com/doi/10.1111/jace.20314)

Abstract

Glass powders with compositions within the ZnO–MgO–Al2O3–SiO2 system (without the addition of nucleating agents) were synthesized by spray-drying and carefully crystallized to obtain stuffed quartz solid solutions (Qz-ss). The substitution of Zn by Mg causes an increase in the crystallization temperature and the composition of Qz-ss varies during their formation, highlighting a nonisochemical precipitation with respect to the parent glass. A change from a low-temperature modification of Qz-ss to a high-temperature modification was visible for Qz-ss containing 80 or 90 mol% SiO2. The high-temperature modification of Mg- and (Zn,Mg)-Qz-ss displays negative thermal expansion for SiO2 content equal to 90 mol%, but a positive one for 80 and 67 mol%. In contrast, the high-temperature modifications of Zn-Qz-ss show a negative thermal expansion for the three SiO2 contents studied. The properties of (Zn,Mg)-Qz-ss containing 67 mol% SiO2 cannot be predicted by a linear interpolation between Zn-Qz-ss and Mg-Qz-ss. A (Zn,Mg)-Qz-ss with zero thermal expansion was crystallized by modulating SiO2 content and Mg/Zn ratio.

2024

- Gomes Fernandes, R., Selle, S., Wagner, T., Menzel, M., Deubener, J.

Local fluctuation of the relative density of glass powders over the entire viscous sintering process

Journal of Non-Crystalline Solids 625 (2024) 122746, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2023.122746.

(https://www.sciencedirect.com/science/article/pii/S0022309323006117)

Abstract

Using high-resolution X-ray computed tomography and 3D image analysis, the global relative density was determined and fluctuations in relative density were localized and quantified in a series of sintered glass bodies made of 80 μm glass spheres over the entire sintering process. A representative volume element (RVE) in the sintered body was divided into cubic volumes of 500, 250 and 125 µm edge length by an automatic segmentation routine. It was found that the expected decrease in coarseness C from the initial to the final sintering stage is interrupted by an intermediate stage with highest C and a characteristic bimodal density distribution. The bimodality of the intermediate stage is due to spatially separated denser arrangements within the RVE with closed pores and less dense arrangements with a network of interconnected or open pores. The spatial heterogeneity is biased in the z-direction due to friction caused by adhesion with the substrate.

- Zandonà, A., G. Helsch, J. Deubener

Nomenclature of functional crystals in glass-ceramics: A recommendation based on aluminosilicate solid solutions

Journal of Non-Crystalline Solids 633 (2024) 122954, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2024.122954.

(https://www.sciencedirect.com/science/article/pii/S0022309324001352)

Abstract

The need for a homogeneous nomenclature has become particularly acute due to the increasing digitization and open accessibility of research data provided by peer-reviewed scientific publishers and other online repositories and databases, and the resulting big-data mining approaches. Therefore, basic guidelines for a general nomenclature system based on the crystallographic structure are presented to enable scientists, engineers and technologists to name the crystalline phases detected in glass-ceramics as uniformly and unambiguously as possible and exemplified by quartz, keatite and indialite solid solutions. The adoption of a standardized nomenclature is essential to ensure effective use of the vast scientific knowledge available today in accordance with the FAIR (findable, accessible, interoperable, reusable) data management systems.

- Ueberricke, L., T. Murata, H. Ikeda, S. Nakane, J. Deubener

Crystal Growth in Oxide Melts – From CALPHAD Thermodynamic Modeling to Statistical Prediction

Acta Materialia 273 (2024) 119960, ISSN 1359-6454,

doi.org/10.1016/j.actamat.2024.119960.

(https://www.sciencedirect.com/science/article/pii/S1359645424003124)

Abstract

Using a thermodynamic database approach (CALPHAD), thermodynamic parameters of crystal growth of 31 stoichiometric and non-stoichiometric glasses are calculated. Together with these parameters, the measured growth rates, taken from both literature and in-house measurements, are interpreted in the framework of four interface-controlled growth models: normal, screw-dislocation, 2D growth and a combination of the latter two. A multiple linear regression model is used to explain the maximum crystal growth rate and viscosity at the liquidus temperature with the above growth mechanisms. This finding seems to reflect a general trend and can therefore be used to avoid unintentional devitrification phenomena or to derive their temperature-time range based on the sole knowledge of glass viscosity and liquidus temperature. In future research, it can also help to reduce the experimental workload required for the development of novel glasses and glass-ceramics.

- Zhang, X., Sibari, R., Chakraborty, S., Baz, S., Gresser, G.T., Benner, W., Brämer, T., Steuernagel, L., Ionescu, E., Deubener, J., Beuermann, S., Ziegmann, G. and Wilhelm, R.

Epoxy-Based Carbon Fiber-Reinforced Plastics Recycling via Solvolysis with Non-Oxidizing Methanesulfonic Acid.

Chemie Ingenieur Technik (2024)

https://doi.org/10.1002/cite.202300243

Abstract

The urgent requirement for efficient recycling strategies in the wind energy industry prompted this study to explore the behavior of methanesulfonic acid (MSA) in the solvolysis of carbon fiber-reinforced plastics (CFRP), as an alternative to standard solvents and acids. For the investigation, two layers of carbon fibers, infused with amine-based epoxy through a vacuum-assisted resin infusion process, were applied. The results showed that MSA was the most effective solvent for the solvolysis of CFRP, compared to other investigated common acids. The recycled products demonstrated satisfactory properties for both the matrix and fiber, which were comparable to those of the virgin materials.

- Alessio Zandonà, Beatriz Paiva Da Fonseca, Gundula Helsch, Vinzent Olszok, Michael J. Pitcher, Haytem Bazzaoui, Alfred P. Weber, Mathieu Allix, Joachim Deubener

Structural features and thermal expansion of zinc aluminosilicate quartz solid solutions

Journal of the European Ceramic Society (2024), ISSN 0955-2219

doi.org/10.1016/j.jeurceramsoc.2024.05.046.

(https://www.sciencedirect.com/science/article/pii/S0955221924004631)

Abstract

Zinc aluminosilicate (ZAS) glasses were synthesized along the peraluminous join (SiO2 contents between 95 and 50 mol%) by melt-quenching or sol-gel spray-drying and subjected to controlled heat treatments to obtain ZAS quartz solid solutions (Zn-Qz-ss). The precipitation of Zn-Qz-ss is non-stoichiometric with respect to their parent glass and the crystals undergo a compositional evolution during annealing, even in absence of secondary crystalline phases. Near-hexagonal high-quartz-like crystals with negative thermal expansion (down to −3 × 10−6 K−1) can be obtained in the range 50–80 mol% SiO2, while SiO2-richer crystals exhibit positive thermal expansion at room temperature (up to 29 × 10−6 K−1). Zn2+ ions occupy two distinct positions within the structural channels of quartz, with a strong preference for 4-fold coordination. In analogy to lithium aluminosilicate quartz solid solutions (Li-Qz-ss), the low-to-high phase transition exhibits a linear correlation to the composition of the crystals.

- Alessio Zandonà, Victor Castaing, Alexander I. Shames, Gundula Helsch, Angela Pirri, Guido Toci, Joachim Deubener, Mathieu Allix, Adrian Goldstein

Effect of the interaction between basicity and reductive character of melting atmosphere – both extreme – on the oxidation and coordination states assumed by transition metals when doped to silicate glasses

Journal of Non-Crystalline Solids 637 (2024) 123038, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2024.123038.

(https://www.sciencedirect.com/science/article/pii/S0022309324002175)

Abstract

The influence of an extremely reductive melting atmosphere on the oxidation and coordination states adopted by transition metals in an ultrabasic host was evaluated. An invert glass (46SiO2·11Na2O·21CaO·22BaO, basicity = 0.71) was synthesized in container-less conditions, on a jet of Ar−5%H2. Performed measurements included optical absorption, optical emission and electron paramagnetic resonance spectroscopy. The results revealed that the used atmosphere dramatically decreases the oxidation state(s) dopants assume, compared to those stable under oxidative melting in such a host. After reductive melting: (i) Ti3+ appears alongside Ti4+; (ii) V3+ is added to V5+; (iii) Mn2+ fully substitutes Mn3+ and Mn5+; (iv) Cu2+ is entirely replaced by Cu+and Cu0. These results could be rationalized considering the action of additional factors like ligand-field stabilization energy, ionization energy and special filling numbers of the 3d-subshell. They modulate the interaction between basicity and atmosphere redox character, in a way specific to each transition metal.

- Bornhöft,H., J. Deubener

Processes to ensure adherence and their kinetics at the interface between vitreous porcelain enamels and sheet steel

Email – Mitteilungen des Deutschen Emailverbandes e.V. 72 (2024) 20-23

Abstract

To unravel the effect of minor steel components on enamel adherence, 22 sheet steals (different producers, 0.5-3 mm thick) were subjected to a standardized coating and firing protocol (one coat, one fire at 800-840 °C for 1-20 min) and a subsequent deep drawing test. Chemical composition of sheet steal was analysed using optical emission spectroscopy (Spark-OES), while line-scans across the enamel-steel interface were recorded using electron microscopy and energy dispersive X-ray spectroscopy (EDX). To collect chemical information from larger lateral sizes (up to 80 mm2), depth-profiles across the interface were carried out using secondary neutral-mass spectrometry (SNMS). Mechanical adherence of the enamel on the sheet steal was assessed from the formation of an interface layer, which is uncovered by the deep drawing test and can be scaled with an adherence index F between 0 and 100%. The kinetic analysis includes time-temperature-adherence index (T-T-F) representations, which emphasize that interface processes and concurrent adherence development (F up to 100%) are generally fast (1-2 min) in the considered temperature range. However, they also reveal that certain minor elements, such as phosphorous can cause a noticeably restriction in the growth of F and insufficient adherence layer formation. Gogula, S., H. Bornhöft, L. Wondraczek, M. Sierka, A. Diegeler, R. Müller, J. Deubener

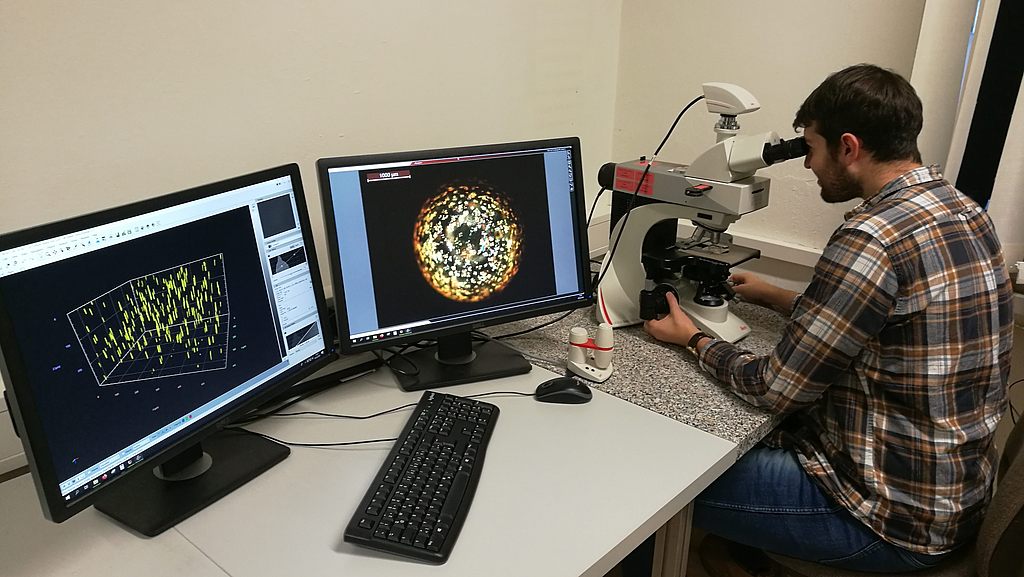

Optical Real-Time Castability Evaluation for High-Throughput Glass Melting

Glass Europe 2 (2024) 83-93

doi.org/10.52825/glass-europe.v2i.1359

Abstract

A novel optical real-time method for evaluating the castability of glass forming melts for laboratory furnaces is presented. The method is based on the analysis of top view images of the melt surface inside the crucible during melting after being subjected to a small mechanical impulse. In this way, the melt surface is excited to oscillate. The difference in contrast between two images taken in quick succession scales with the viscosity, with a larger difference occurring at lower viscosities. The method is designed as an instrument for the in-line evaluation of the castability for a high-throughput glass melting system as part of the joint project “GlasDigital” in the framework of the German Platform Material Digital initiative but is applicable to other laboratory furnaces as well.

Selle, S., Bornhöft, H., Wendel, J. C., Deubener, J.

Overview of the Precipitates in a Ground-Coat Vitreous Enamel Using Analytical TEM

Glass Europe 2, 95–114

doi.org/10.52825/glass-europe.v2i.1269Abstract

Precipitates in the ground-coat vitreous enamel, which form when the dried coating is fired and cooled on sheet steel, are essential for the function of the enamelling. They lead to an interlocked metal-glass interface and are triggered by redox-driven processes in a glass layer saturated with iron. Using analytical transmission electron microscopy, it is shown that alloys of the Fe-Co-Ni-Cu system not only precipitate near the interface, where they contribute to adhesion through an interlocking interface, but also form nanocrystallites that are finely distributed in the enamelled glass to a depth determined by the diffusivity of Fe2+ (30 μm after four minutes of firing) and probably contribute to the toughening of this glass layer. The saturation with iron also prevents the segregation of the glass flux and opacifier calcium fluoride, which only occurs far from the interface in the chemically unmodified base glass. At the metal-glass interface, however, phosphorus traces diffuse from the steel and precipitates in the form of calcium phosphate needles that grow into the enamelled glass.

2023

- Murata, T., S. Nakane, H. Yamazaki, R. Al-Mukadam, J. Deubener

Heterogeneous crystal nucleation, viscosity and liquidus temperature in the system lithium metasilicate – lithium disilicate

Journal of Non-Crystalline Solids 605 (2023) 122170, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2023.122170.

(https://www.sciencedirect.com/science/article/pii/S002230932300039X)

Abstract

The heterogeneous crystal nucleation of five glasses along the compositional join between lithium disilicate and lithium metasilicate was studied by differential scanning calorimetry (DSC) and high-temperature optical microscopy (HTOM). In addition to DSC and HTOM, liquidus temperature and viscosity were measured. DSC and HTOM consisted of 147–378 repetitive cooling runs for each melt and method. DSC and HTOM showed that the crystal nucleation rate was highest for a glass of ∼63 mol% silica and that the first crystallite consisted of intergrown lithium metasilicate and quartz. In the case of DSC, primary crystallization of lithium disilicate was additionally observed, which was treated as an oxygen-related artifact. The viscosity at the maximum nucleation rate was almost constant for each melt, while the liquidus temperature resulting from the linear extrapolation of the DSC-endotherm for a heating rate of 0 K min−1 was 20–30 K higher than that calculated from thermodynamic properties.

- Zandonà, A., V. Castaing, A.I. Shames, G. Helsch, J. Deubener, A.I. Becerro, M. Allix, A. Goldstein

Oxidation and coordination states assumed by transition metal dopants in an invert ultrabasic silicate glass

Journal of Non-Crystalline Solids, 603 (2023) 122094, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2022.122094.

(https://www.sciencedirect.com/science/article/pii/S0022309322006883)

Abstract

An ultrabasic invert silicate glass (46SiO2·11Na2O·21CaO·22BaO, optical basicity index equal to 0.71) was synthesized (O2 atmosphere) and used as host for various transition metal dopants. Optical absorption, emission and electron paramagnetic spectroscopies were used to characterize oxidation and coordination states. Some of the dopants displayed only their maximal oxidation state (Ti4+, V5+, Cr6+, Mo6+ and W6+). Others exhibited mixed valences: (i) Mn3+ was the dominant species, alongside Mn2+ and Mn5+; (ii) stable Fe3+ prevailed, although some Fe2+ was preliminarily suggested by the absorption spectrum; (iii) Co3+ probably accompanied the dominant Co2+ tetrahedral oxide complex; (iv) like in “conventional” silicate glasses, only Ni2+ was detected, though simultaneously located in tetrahedral and octahedral sites (somewhat distorted); (v) Cu+ was surprisingly identified alongside the expected 6-fold coordinated Cu2+. Drastic reduction of the oxygen content in the melting atmosphere led to conversion of Cr6+ to Cr3+, despite the extreme basicity of the host.

Fritzsche, J.O., B. Rüdinger, J. Deubener

Abstract

Slow coarsening of tetragonal zirconia nanocrystals in a phase-separated sodium borosilicate glass

Journal of Non-Crystalline Solids 606 (2023) 122206, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2023.122206.

(https://www.sciencedirect.com/science/article/pii/S0022309323000753)

A Zr4+-containing sodium borosilicate glass (ZNBS) and a zirconium-free reference glass (NBS) were prepared by melt quenching. Thermal analysis revealed two glass transitions, indicating that both glasses exhibit phase separation into boron- and silica-rich domain structures already after quenching to room temperature. Electron micrographs showed that annealing of NBS and ZNBS glasses initiated the coarsening of these domains and the precipitation of metastable t-ZrO2 in the boron-rich matrix of the ZNBS glass. The coarsening kinetics of the silica-rich domains followed the theoretical predictions (power law exponent = 1/3), while the coarsening of the t-ZrO2 crystallites was much slower. The time evolution of the average size of t-ZrO2 nanocrystallites from small angle X-ray scattering (SAXS) and high-temperature X-ray diffraction (HTXRD) experiments revealed a coarsening exponent of ∼1/6. This slow coarsening of t-ZrO2 is assumed to be confined by the domain structure of the primary phase separation.

Di Genova, D., D. Bondar, A. Zandonà, P. Valdivia, R. Al-Mukadam, H. Fei, A.C. Withers, T. Boffa Ballaran, A. Kurnosov, C. McCammon, J. Deubener, T. Katsura

Viscosity of anhydrous and hydrous peridotite melts

Chemical Geology 625 (2023) 121440, ISSN 0009-2541

doi.org/10.1016/j.chemgeo.2023.121440.

(https://www.sciencedirect.com/science/article/pii/S0009254123001407)Abstract

The melt viscosity (η) of anhydrous and hydrous peridotite was investigated using a multipronged approach combining micropenetration viscometry, conventional DSC, flash DSC and Brillouin spectroscopy. Raman spectroscopy measurements were used to verify the absence of crystallization and/or degassing during high-temperature measurements of these extremely reactive glasses and melts, ensuring that the data corresponded to the crystal-free melt viscosity. Based on the experimental data, an accurate description of the viscosity of peridotite melts over thirteen orders of magnitude (from Tg to η ≈ 10−1 Pa s) is provided in a broad range of compositions and oxidation states. Since empirical models predict viscosities that can significantly deviate from measured data to varying degrees, a new model was developed for the temperature- and H2O-dependent viscosity of peridotite melts (up to 12 mol% H2O content).

Zandonà, A., E. Véron, G. Helsch, A. Canizarès, J. Deubener, M. Allix, C. Genevois

Crystallization Mechanism of Gel-Derived SiO2–TiO2 Amorphous Nanobeads Elucidated by High-Temperature In Situ Experiments

Crystal Growth & Design (2023)

doi.org/10.1021/acs.cgd.3c00300

Abstract

SiO2–TiO2 amorphous nanobeads with a TiO2 content up to 50 mol % were synthesized by sol–gel spray drying. Their crystallization during heat treatments was then characterized by in situ high-temperature techniques including X-ray diffraction, Raman spectroscopy, and particularly high-resolution transmission electron microscopy. Intrinsic nanoscale chemical modulations could be identified already in the as-prepared nanobeads and were shown to play a major role for the nonisochemical precipitation of TiO2 nanocrystals during heating experiments: the size and compositional contrast of such fluctuations progressively evolved and increased until the emergence of long-range ordering. The formation of TiO2 polymorphs occurred according to Ostwald’s rule of stages, with the metastable TiO2(B) phase acting as a precursor to stabilize anatase and rutile. The temporary appearance of TiO2(B) nanocrystals at early annealing stages was interpreted as the first direct experimental observation of subcritical crystalline nuclei.Hampel, S., F. Sand, D.A. Murcia Gonzalez, G. Pepponi, G. Helsch, J. Deubener, T. Schirmer, A. Fittschen, U.E.A. Fittschen

Chelate complexed multi-elemental printing performance of a small and cost efficient picoliter droplet printing device for micro preparation

Spectrochimica Acta Part B: Atomic Spectroscopy, 206 (2023) 106716, ISSN 0584-8547

doi.org/10.1016/j.sab.2023.106716.

(https://www.sciencedirect.com/science/article/pii/S0584854723001039)Abstract

We introduce an inexpensive modular picoliter pipetting device using modified commercially available thermal inkjet cartridges. The system is capable of reliable deposition of 65 elements. The printing solutions were modified to prevent the dissolution of Ni from the nozzle head, keeping those at a pH of >9. Loss of cations to the glass surfaces inside the nozzle head is prevented by forming anionic complexes with ethylenediaminetetraacetic acid in basic conditions. For some elements, e.g., Si, additives like tetramethylammonium hydroxide are necessary.

The volumes of the droplets were obtained, weighing 30,000–360,000 droplets ejected by the printer using a laboratory scale. The droplet volume was within a range of 142–184 pL, depending on the formulation. The delivered elemental masses and the reproducibility were determined using total reflection X-ray fluorescence analysis and inductively coupled plasma optical emission spectrometry. Delivered masses were in the range of 0.98 pg – 11.9 pg per element and droplet.

The shape of deposits of about 31 pg per element was studied using atomic force microscopy, optical microscopy, and confocal laser scanning microscopy. They were mostly spherical and ca. 14 μm in diameter and ca. 2 μm in height. The broad range of printable elements allows for the micro preparation of solid compounds for establishing a grazing incidence X-ray diffraction analysis library. As an example, the MgAl2O4 spinel was synthesized by printing of the formulation and subsequent calcination. Here we show its performance for the preparation of minerals in the context of recycling of critical elements from pyrometallurgical slags.Deubener, J., H. Behrens, R. Müller

An overview on the effect of dissolved water on the viscosity of soda lime silicate melts

Journal of Non-Crystalline Solids X, 19 (2023) 100195, ISSN 2590-1591

doi.org/10.1016/j.nocx.2023.100195.

(https://www.sciencedirect.com/science/article/pii/S259015912300047X)

Abstract

In this review article, the impact of dissolved water on the viscous properties of soda lime silicate melts is addressed against the background of the upcoming switch from natural gas to hydrogen combustion. This change will lead to an increase in the total water content of the glasses by up to 0.4 mol%. In order to better define possible influences of water speciation, water-rich glasses were synthesised under increasing pressure up to the kbar range. It is shown that a distinction must be made between the influence of dissolved OH-groups and H2O-molecules in order to accurately reflect the dependence of isokom temperatures on water content. In addition, an increase of one order of magnitude in the tolerance to higher deformation rates was observed for the range of expected increased water contents during isothermal deformation processes, which is based on the time-temperature superposition principle, i.e. congruent flow curves were determined under isokomal conditions.

Fielitz, P., G. Helsch, G. Borchardt, J. Deubener

Al-26 and O-18 tracer diffusion in a titania-coated sodium aluminosilicate glass

Journal of Non-Crystalline Solids 614 (2023) 122400, ISSN 00223093

doi.org/10.1016/j.jnoncrysol.2023.122400.

(https://www.sciencedirect.com/science/article/pii/S0022309323002661)

Abstract

Although TiO2 is a common nucleating agent in the production of aluminosilicate glass-ceramics, its role as a catalyst for the nucleation of the functional crystal remains unclear. Therefore, the Ti, Al and O mobility was studied in situ using 26Al and 18O tracer diffusion and Ti chemical diffusion experiments in an aluminosilicate melt of albite composition. The albite glass serves as a surrogate for lithium and magnesium aluminosilicate glass-ceramic compositions, as it allows to study atomic mobilities free of crystallisation artefacts. The depth profiles showed that Al mobility increased significantly and became comparable to that of oxygen when Ti simultaneously diffused into the glass. In the absence of Ti, the diffusivity of Al was two orders of magnitude lower than that of oxygen. The co-diffusion coefficients of Ti and Al seem to confirm a proposed preferential structural linkage between Al and Ti species in the network structure of aluminosilicate melts.

Reinsch, S., T. Welter, R. Müller, J. Deubener

Hydrogen Permeability of Tectosilicate Glasses for Tank Barrier Liners

Glass Europe 1 (2023) 1–11.

doi.org/10.52825/glass-europe.v1i.425

Abstract

The permeation of hydrogen gas was studied in meta-aluminous (tectosilicate) glass powders of Li2O×Al2O3×SiO2 (LAS), Na2O×Al2O3×SiO2 (NAS) and MgO×Al2O3×SiO2 (MAS) systems by pressure loading and vacuum extraction in the temperatures range 210–310 °C. With this method, both the solubility S and the diffusivity D were determined, while the permeability was given by the product SD. For all glasses, S was found to decrease with temperature, while D increased. Since the activation energy of diffusion of H2 molecules exceeded that of dissolution, permeation increased slightly with temperature. When extrapolated to standard conditions (25 °C), the permeability of tectosilicate glasses was found to be only 10-22–10-24 mol H2 (m s Pa)-1, which is 8–10 magnitudes lower than most polymers. Thin glass liners of these compositions are expected to be the most effective barrier for tanks of pressurised hydrogen.

Fielitz, P., G. Helsch, J. Löschmann, R. Gustus, G. Borchardt, J. Deubener

Oxygen-18 tracer diffusion in a crystallised lithium-aluminosilicate glass

Journal of Non-Crystalline Solids 616 (2023) 122470, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2023.122470.

(https://www.sciencedirect.com/science/article/pii/S0022309323003368)

Abstract

In this work we present first 18O tracer diffusion data in a crystallized LAS4 glass. The glass of LAS4 composition (close to Li2O⋅Al2O3⋅4SiO2) is free of nucleating agents and has a very low tendency to nucleate crystals in the volume. A thin ZrTiO4 layer (∼70 nm thick) was deposited by argon ion beam sputtering and served to preferentially nucleate high-quartz solid solution crystallites from the surface. All samples crystallised at the very early stage of the respective diffusion annealing time, i.e. virtually before the onset of the 18O tracer diffusion. The microstructure of the crystallised LAS glass is composed of crystalline domains (high-quartz solid solutions and keatite solid solutions) and a glassy phase of low viscosity in the domain boundaries. The oxygen transport occurs predominantly in the glassy phase of the domain boundaries and is faster than the transport of network forming cations or larger configurations in the glassy phase.

Processes to ensure adherence and their kinetics at the interface between vitreous porcelain enamels and sheet steel

Hansjörg Bornhöft, Joachim Deubener

International Enamellers Congress, Kyoto, Japan, May 8-11, 2023, 4 (E-04)

ieiworlddotorg.wordpress.com/congress/

ieiworlddotorg.files.wordpress.com/2023/10/final-international-enamellers-congress.pdf

Valdivia, P., A. Zandonà, A. Kurnosov, T.B. Ballaran, J. Deubener, D. Di Genova

Are volcanic melts less viscous than we thought? The case of Stromboli basalt

Contrib Mineral Petrol 178 (2023) 45

doi.org/10.1007/s00410-023-02024-w

Abstract

Melt viscosity is one of the most critical physical properties controlling magma transport dynamics and eruptive style. Although viscosity measurements are widely used to study and model the flow behavior of magmas, recent research has revealed that nanocrystallization of Fe–Ti-oxides can compromise the reliability of viscosity data. This phenomenon can occur during laboratory measurements around the glass transition temperature (Tg) and lead to the depletion of iron and titanium in the residual melt phase, with a significant increase in viscosity. Accurate viscosity measurements play a crucial role in determining the reliability of empirical models for magma viscosity, which are used to evaluate eruptive scenarios in hazardous areas. Here, we quantify the reliability of empirical models by elaborating a new viscosity model of Stromboli basalt that relies exclusively on viscosity data obtained from nanocrystal-free samples. We show that empirical models so far used to estimate melt viscosity at eruptive conditions overestimate Stromboli viscosity by a factor ranging between 2 and 5. In the context of numerical modelling of magmatic processes at Stromboli volcano, we analyse and interpret this finding. Based on our findings, we draw the conclusion that Stromboli basalt is anticipated to ascend from the storage area to the vent at a faster rate than previously hypothesized.

Paiva Da Fonseca, B., Zandonà, A., Helsch, G., & Deubener, J.

Co2+-Stuffed Quartz Solid Solutions With Zero Thermal Expansion Synthesized by Sol-Gel Spray-Drying

Glass Europe1 (2023) 25–36

doi.org/10.52825/glass-europe.v1i.460

Abstract

Glassy nanobeads of nominal composition CoO·Al2O3·4SiO2, doped with some Li2O to foster their crystallization, were synthesized by spray-drying from a methanol-based solution. Heat treatments at 850 °C and 900 °C successfully induced the formation of quartz solid solution crystals, whose thermal expansion was found to be very close to zero between 25 °C and 625 °C (average linear coefficient of thermal expansion CTE = 0.3 x 10-6 K-1). Annealing at higher temperatures induced structural unstuffing of the solid solutions, accompanied by the parallel formation of CoAl2O4 spinel and by a color shift of the powders from purple to blue. Sol-gel spray-drying stands out as a highly versatile synthesis method that can harness the thermal expansion tunability of quartz solid solution phases within a (quasi) lithium-free compositional landscape.

Zandonà, A., A. Scarani, J. Löschmann, M.R. Cicconi, F. Di Fiore, D. de Ligny, J. Deubener, A. Vona, M. Allix, D. Di Genova

Non-stoichiometric crystal nucleation in a spodumene glass containing TiO2 as seed former: Effects on the viscosity of the residual melt

Journal of Non-Crystalline Solids 619 (2023) 122563, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2023.122563.

(https://www.sciencedirect.com/science/article/pii/S0022309323004295)

Abstract

A spodumene glass (LiAlSi2O6), doped with 4 mol% TiO2 as a nucleating agent, was synthesized by containerless melting. Its accurate viscosity characterization by micropenetration viscometry or calorimetry is shown to be very challenging in the vicinity of the glass transition, due to the unpreventable occurrence of thermally activated non-stoichiometric crystal nucleation, closely overlapping the relaxation into the liquid state. TiO2 crystal nucleation brings about a compositional modification of the residual melt, with an associated increase in measured viscosity by up to 2 log units. A careful experimental approach and a profound understanding of seed formation are essential to circumvent or at least minimize such inaccuracies, getting as close as possible to the viscosity of the parent homogeneous melt.

Gomes Fernandes, R., Al-Mukadam, R., Bornhöft, H., Reinsch, S., Müller, R., Selle, S., Deubener, J.

Viscous Sintering of Acid Leached Glass Powders

Glass Europe 1 (2023) 37–53

doi.org/10.52825/glass-europe.v1i.681

Abstract

The process of viscous flow sintering is a phenomenon that is closely linked to the surface properties of the glass particles. In this work, we studied the extreme case of acid-leaching of soda-lime-silicate glass beads of two different particle size distributions and its effects on non-isothermal viscous sintering of powder compacts. Depth profiling of the chemical composition after leaching revealed a near-surface layer depleted in alkali and alkaline earth ions, associated with concurrent hydration as mass loss was detected by thermogravimetry. Heating microscopy showed that acid treatment of glasses shifted the sinter curves to higher temperatures with increasing leaching time. Modelling of the shrinkage with the cluster model predicted a higher viscosity of the altered surface layer, while analysis of the time scales of mass transport of mobile species (Na+, Ca2+ and H2O) during isochronous sintering revealed that diffusion of Na+ can compensate for concentration gradients before sintering begins. Also, exchanged water species can diffuse out of the altered layer, but the depletion of Ca2+ in the altered surface layer persists during the sinter interval, resulting in a glass with higher viscosity, which causes sintering to slow down.

2022

Scarani, A., Vona, A., Di Genova, D. Al-Mukadam, R., Romano, C., Deubener, J.

Determination of cooling rates of glasses over four orders of magnitude.

Contrib Mineral Petrol177, 35 (2022).

doi.org/10.1007/s00410-022-01899-5

Abstract

Volcanic materials can experience up to eleven orders of magnitude of cooling rate (qc) starting from 10–5 K s−1. The glassy component of volcanic material is routinely measured via differential scanning calorimeter (DSC) to obtain qc through the determination of the glass fictive temperature (Tf). Conventional DSC (C-DSC), which has been employed for decades, can only access a relatively small range of qc (from ~ 10–2 to ~ 1 K s−1). Therefore, extrapolations up to six orders of magnitude of C-DSC data are necessary to derive qc of glasses quenched both at extremely low and high qc. Here, we test the reliability of such extrapolations by combining C-DSC with the recently introduced flash calorimetry (F-DSC). F-DSC enables to extend the qc exploration up to 104 K s−1. We use three synthetic glasses as analogs of volcanic melts. We first apply a normalization procedure of heat flow data for both C-DSC and F-DSC to derive Tf as a function of experimental qc, following the “unified area-matching” approach. The obtained Tf–qc relationship shows that Arrhenius models, widely adopted in previous studies, are only valid for qc determination within the calibration range. In contrast, a non-Arrhenius model better captures qc values, especially when a significant extrapolation is required. We, therefore, present a practical “how-to” protocol for estimating qc using DSC.

Bornhöft, H., Deubener J.

Enamelling ability and adherence of enamels on heterogeneous types of steel with varying proportions of accompanying elements

Email – Mitteilungen des Deutschen Emailverbandes e.V. 70 (2022) 4-18

Report available: www.tib.eu/de/suchen/id/TIBKAT:1809317940/Emaillierf%C3%A4higkeit-und-Haftung-von-Emails-auf-heterogenenAbstract

Various European manufacturers provided 21 different types of sheet steel suitable for enamelling. Two commercially available ground enamels (RTU, Ready To Use) and a direct white enamel (RTU) from two enamel frit manufacturers were used in the experiments. Enamelling of the test specimens was performed in an electric furnace with increasing firing duration. The characterization comprised the primary adherence test by deep drawing the enamelled sheet steel using a standard testing machine. The adherence properties were determined based on the type and extent of the destroyed enamel surface and the quantification of the adherence layer proportions. By scanning the fracture pattern and computer-aided evaluation, the results were calculated as an adherence index, with 100 percent being the target value as complete coverage with an adherence layer. The electron microscopic examination of polished sections of all test specimens included the topographical representation of sheet steel, adherence layer and enamel as well as the recording of chemical profiles with 16 relevant elements using EDX from the steel into the enamel layer.

From the large number of individual investigations, it was possible to gain important information on the reactions occurring during firing and on the formation of the adherence layer between sheet steel and enamel, and compared them with the alloy components present in the sheet steel. According to the state of knowledge achieved up to now, higher alloyed steel sheets (Fe content: 98.6 mass percent) can be enamelled just as perfectly as lower alloyed steel sheets (Fe content: 99.7 mass percent). The quantities of alloying elements that change certain properties of the sheet steel, such as resistance to scaling (e.g. due to the elements silicon or carbon), i.e. the restriction of the oxidizing ability, or a subsequent refinement by phosphatizing to prevent corrosion, are of particular importance for the enamelling ability.

An important prerequisite for successful enamelling with intensive adherence is the formation of a fresh iron oxide layer on the steel surface, which is formed during the firing process, with immediate dissolution of the FeO in the enamel melt. Depending on the firing duration, a characteristic chemical gradient of the Fe concentration in the enamel is found. This pronounced Fe concentration gradient should ensure a higher fraction of chemical bonds in the form of Fe – O – Si bridges close to the metal-to-enamel interface. In the case of hot-rolled steel sheets, the existing iron oxide layer of several microns must be removed completely before the enamelling, as otherwise, no adherence occurs. Obviously, this “old” iron oxide layer interferes with the redox reactions that take place normally at the surface due to the adherence oxide being present in the ground enamel. The “old” oxide layer is evidently very slow in reacting and hardly dissolves in the melt, or only with time delay. A sufficient amount of fresh FeO can only be formed on the steel if enough oxygen is present in the atmosphere. With the progressive dissolution of FeO a super saturation of iron in the enamel melt occurs and, in presence of adherence metals, alloys can precipitate at the interface showing elevated concentrations of cobalt, nickel and copper. Chemical analyses confirm this precipitation as a secondary formation due to higher amounts of these metals regarding to the base metal. The docking of the precipitated, droplet-shaped aggregating metal alloy phases on the sheet steel surface leads to a characteristic structure with a large specific surface and correspondingly high mechanical interlocking of metal and enamel. The process is supported by the sharp decrease in melt viscosity during the dissolution of FeO in the melt. Tests in an inert gas atmosphere with argon or nitrogen show that the reactions described for the formation of an adherence layer do not occur and therefore no adherence can arise. For this reason, checking the furnace atmosphere with sufficient atmospheric oxygen is of huge importance for the success of the enamelling process.

Löschmann,J., Fielitz, P., Helsch,G., Bornhöft, H., Cassar, D.R. , Borchardt, G., Deubener, J.

Accelerated crystal growth in a lithia aluminosilicate glass

Acta Materialia (2022) 117837, ISSN 1359-6454,

doi.org/10.1016/j.actamat.2022.117837.

(https://www.sciencedirect.com/science/article/pii/S1359645422002245)Abstract

No viscosity change in the vicinity of the crystal/melt interface is to be expected for crystal growth in silicate systems at constant temperature in a deeply undercooled isochemical melt. In most experimental studies, however, absolute chemical conformity is not realized and the formation of an interfacial zone with presumably strongly altered viscosity will occur. In the present investigation isolated Li2O⋅Al2O3⋅4SiO2 (LAS4) single crystals grew in a slightly alumina deficient base glass at temperatures above glass transition. Due to the depletion of alumina (and the enrichment of excess components and impurities) of the continuously growing interfacial zone (“shell”), its viscosity will change. Dedicated experiments showed that the viscosity of the interfacial zone is up to 7 orders of magnitude lower than the viscosity of the base glass. The decreased viscosity at the crystal growth front is assumed to cause the experimentally observed increase of the crystallisation velocity with the crystal radius. This behaviour can be quantitatively modelled introducing a linear decrease of the activation enthalpy with the crystal radius. Obviously, the proposed model can be likewise used in the opposite case, i.e. for an increasing viscosity of the interfacial zone during crystal growth. According to the standard concept of a fractional viscosity relation, a coupling factor can formally be extracted from the comparison between the experimentally determined activation enthalpies of the crystal growth velocity and of the base glass viscosity. The resulting unrealistically low numerical value indicates that it is not the high viscosity of the base glass, but the lower viscosity of the interfacial zone that must be considered for the determination of a physically meaningful coupling factor.

Keywords: 0non-linear crystal growth kinetics; lithia aluminosilicate glass; glass-ceramics; viscosity

Tielemann, C., Reinsch, S., Maaß, R., Deubener, J.,Müller, R.

Internal nucleation tendency and crystal surface energy obtained from bond energies and lattice data

Journal of Non-Crystalline Solids X (2022) 100093, ISSN 2590-1591

doi.org/10.1016/j.nocx.2022.100093.

(https://www.sciencedirect.com/science/article/pii/S2590159122000139)

Abstract

We present an easy-to-apply method to predict structural trends in the internal nucleation tendency of oxide glasses. The approach is based on calculated crystal fracture surface energies derived from easily accessible diatomic bond energy and crystal lattice data. The applicability of the method is demonstrated on literature nucleation data for isochemically crystallizing oxide glasses.

Keywords: Glass; Nucleation tendency; Fracture surface energy; Crystal lattice; Bond energy

Maiwald, M.; Bornhöft, H., Deubener, J.

Simultaneous thermal analysis and evolved gas analyses by mass spectrometry on mixtures of steel and ground coat enamel in different atmospheres

Email – Mitteilungen des Deutschen Emailverbandes e.V. 70 (2022) 24-35Abstract

The method of simultaneous thermal analysis is used to identify reaction processes between steel and ground coat enamel. The thermal behaviour of mixtures of steel chips of different steel grades and one RTU ground coat powder is characterized under the influence of different gas atmospheres (standard air and nitrogen) with regard to mass change, differential thermoanalytical signal and emission of gas as well as gas species. The results of the measurements carried out prove that more intensive exothermic signal curves are recognized when oxygen is present in the measuring atmosphere. However, the thermogravimetric data in air showing a pronounced increase in mass in the range of 5-8 percent up to the end of the test are much more revealing, while in a nitrogen atmosphere only a very small loss in mass in the range of 0.05 to 0.2 percent is measured.

Gas emissions of the species H2O and CO2 are registered in both measurement atmospheres, although the respective emission peaks are at different temperatures. While adsorbed water shows a peak in the ion current signal at around 100 °C with low intensities, the enhanced emission peaks at temperatures around 450-500 °C are assigned to the released H2O from the decomposition reaction of clay with chemically combined water. In a nitrogen atmosphere, these peaks are shifted to lower temperatures.

The evaluations of CO2 emissions yield different results that raise questions. A low-intensity CO2 peak is detected in all steel-ground coat mixtures examined both in air at around 280 °C and in N2 at ~310 °C, which is in large part related to the oxidation of organic material from the clay. Of interest is the CO2 gas emission process at temperatures above 550 °C. While some samples show CO2 release (in air and N2) with pronounced peaks, the other steel-ground coat mixtures either lack these peaks or have CO2 ion current signals just barely above background. The reason for this different behaviour is not yet fully understood especially in nitrogen atmosphere. A higher carbon content in the volume of the steel sheets may play a role, while the surface of the enamel steel is largely decarburized. More in-depth analyses of this could no longer be carried out as part of the student project.

Fielitz, P., Cassar, D.R., Yuritsyn, N.S., Abyzov, A.S., Fokin, V.M., Borchardt, G., Deubener, J.

Decelerated crystal growth in a soda-lime-silica glass

Journal of Non-Crystalline Solids, 596 (2022) 121879, ISSN 0022-3093,

doi.org/10.1016/j.jnoncrysol.2022.121879.

(https://www.sciencedirect.com/science/article/pii/S0022309322004744)

Abstract

Isolated Na2O⋅2CaO⋅3SiO2 (NC2S3) single crystals grew at temperatures above glass transition in a melt with a slight soda excess. The enrichment of Na in the continuous solid solution Na4+2zCa4–z[Si6O18] (with 0 ≤ z ≤ 1) upon crystallisation causes a depletion of soda of the growing interfacial diffusion zone. Therefore its viscosity will change. Experimental data and idealized model calculations of the viscosity show the same trend and indicate that the viscosity of the interfacial zone would be up to several orders of magnitude higher than the viscosity of the melt. This increased viscosity at the crystal growth front and the experimentally observed decrease of the crystallisation velocity with crystal size suggest a linear increase of the effective activation enthalpy of the diffusional transport through the diffusion zone with crystal size, which allows to quantitatively model crystal growth data of the NC2S3 glass investigated.

Heuser, L, Nofz, M., Müller, R.,Deubener, J.

Silver dissolution and precipitation in a Na2O-ZnO-B2O3 metallization paste glass

Int J Appl Glass Sci. 2022, 2041-1286

doi.org/10.1111/ijag.16613

Abstract

Thermally stimulated interactions between silver and glass, i.e., silver dissolution as Ag+ and precipitation as Ag0 were studied in two glass series of molar target composition xAg2O-(19-x)Na2O-28ZnO-53B2O3 with x = 0, 0.1, 0.5, 5 and (19Na2O-28ZnO-53B2O3)+yAg2O with y = 0.01, 0.05. These act as model for low-melting borate glasses being part of metallization pastes. The occurrence of metallic silver precipitates in melt quenched glass ingots demonstrated that silver dissolved only in traces (< 0.01 mol%) in the glasses. The dissolved silver was detected by means of Raman and EDX spectroscopies. Increasing x in the batch could not lead to a significant increase of the silver ion fraction in the glass as possible in binary silver borate glasses. In situ observation of heated AgNO3 mixed with the base glass frit in a hot stage microscope showed that Ag0 precipitation occurs already at the solid state. At higher temperatures, small droplets of liquid silver were found to move freely within the melt, while coalescence caused a stepwise increase of their size. These results contribute to the understanding of formation of silver precipitates in metallization pastes described in the literature.

Zandonà, A., E. Chesneau, G. Helsch, A. Canizarès, J. Deubener, V. Montouillout, F. Fayon, M. Allix

Glass-forming ability and structural features of melt-quenched and gel-derived SiO2-TiO2 glasses

Journal of Non-Crystalline Solids, 598 (2022) 121967, ISSN 0022-3093

doi.org/10.1016/j.jnoncrysol.2022.121967

(https://www.sciencedirect.com/science/article/pii/S0022309322005622)

Abstract

SiO2-TiO2 glasses produced by aerodynamic levitation coupled to laser heating or by sol-gel spray-drying were compared to highlight their structural differences. Glass formation was possible by melt-quenching up to 10 mol% TiO2, while higher contents led to devitrification. Raman spectroscopy and solid-state 17O and 29Si magic-angle-spinning nuclear magnetic resonance confirmed the clear emergence of Ti-O-Si bonds and a tetrahedral oxygen coordination of Ti4+ leading to full network connectivity, as also substantiated by the synthesis of TiO2-doped cristobalite. In gel-derived glasses, water content induced partial network depolymerization, thereby enhancing the solubility of TiO2 in the hydrous silicate matrix. However, full dehydration during heating proved challenging due to a competing tendency towards devitrification: the glass-forming range in the anhydrous binary SiO2-TiO2 system does not therefore appear to be significantly enlarged by the sol-gel synthesis route.Scarani, A.; A. Zandonà, F. Di Fiore, P. Valdivia, R. Putra, N. Miyajima, H. Bornhöft, A. Vona, J. Deubener, C. Romano, D. Di Genova

A chemical threshold controls nanocrystallization and degassing behaviour in basalt magmas

Commun Earth Environ 3 (2022) 284

doi.org/10.1038/s43247-022-00615-2Abstract

An increasing number of studies are being presented demonstrating that volcanic glasses can be heterogeneous at the nanoscale. These nano-heterogeneities can develop both during viscosity measurements in the laboratory and during magma eruptions. Our multifaceted study identifies here total transition metal oxide content as a crucial compositional factor governing the tendency of basalt melts and glasses towards nanolitization: at both anhydrous and hydrous conditions, an undercooled trachybasalt melt from Mt. Etna readily develops nanocrystals whose formation also hampers viscosity measurements, while a similar but FeO- and TiO2-poorer basalt melt from Stromboli proves far more stable at similar conditions. We therefore outline a procedure to reliably derive pure liquid viscosity without the effect of nanocrystals, additionally discussing how subtle compositional differences may contribute to the different eruptive styles of Mt. Etna and Stromboli.

2021

- P. Stabile, S. Sicola, G. Giuli, E. Paris, M.R. Carroll, J. Deubener, D. Di Genova

The effect of iron and alkali on the nanocrystal-free viscosity of volcanic melts: A combined Raman spectroscopy and DSC study

Chemical Geology 559 (2021) 119991, ISSN 0009-2541

https://doi.org/10.1016/j.chemgeo.2020.119991

(http://www.sciencedirect.com/science/article/pii/S0009254120305301)

Abstract

The iron coordination, its oxidation state (Fe2+/Fetot.), and alkali ratio [Na/(Na + K)] greatly influence the structure and thus the viscosity of volcanic melts, which is known to play a key role in the dynamics of volcanic eruptions. Furthermore, it has been recently reported that volcanic melts can suspend iron-bearing nanocrystals and this makes it difficult to isolate and quantify the chemical contribution to the viscosity of magmas.

Here, we present Raman spectroscopic and differential scanning calorimetry (DSC) data on nanocrystal-free peralkaline rhyolites with different Fe2+/Fetot. (0.15–0.84) and Na/(Na + K) (0–1) molar ratios. Raman spectra are used to infer the structural changes occurring with varying iron oxidation state and alkali content, whereas the combination of Raman spectroscopy and DSC measurements allow the characterization of the anhydrous nanocrystal-free viscosity as a function of temperature. Results suggest that at similar and high Fe2+/Fetot. ratio the Raman spectral feature controlled by the iron coordination changes with Na/(Na + K). Conversely, the change of alkali content at a fixed Fe2+/Fetot. ratio results in a variation of the spectral feature that reflects the size distribution of rings of tetrahedra in the melt structure.

We further discuss the implications of our findings for magma transport and estimate that the viscosity of anhydrous peralkaline rhyolites at the eruptive temperature of 750 °C can increase up to 3.5 log units when Fe2+/Fetot. and Na/(Na + K) ratios decrease contemporaneously from 0.84 to 0.15 and from 1 to 0, respectively. Finally, the comparison of our viscosity data with those from the literature suggests that the DSC-approach presented and adopted in this study is independent on chemical composition and thus can be used also to retrieve the effect of nanocrystals on the viscosity of volcanic melts. The results presented here have profound implications for the modelling of magma viscosity.

Keywords: Peralkaline rhyolites; Raman spectroscopy; Alkali effect; Iron oxidation state; Viscosity

- R. Al-Mukadam, A. Zandonà, J. Deubener

Kinetic fragility of pure TeO2 glass

Journal of Non-Crystalline Solids 554 (2021) 120595

https://doi.org/10.1016/j.jnoncrysol.2020.120595

Abstract:

Pure TeO2 glass was prepared in a flash differential scanning calorimeter by applying fast quenching rates to a TeO2 melt. Matching cooling and heating rates of up to 30,000 K s−1 were then used to determine the respective fictive temperatures, corresponding to viscosity values as low as 105.3 Pa s. The interdependence between calorimetric data and viscosity was verified and fine-tuned for this compositional system utilizing sodium tellurite glasses. The fragility index of pure TeO2 (m = 64) is by far the highest reported for a single-component oxide melt.

Keywords: Glass; TeO2; Sodium tellurite; FDSC; Fragility; Viscosity

T. Waurischk, R. Müller, H. Behrens, J. Deubener

Crack growth in borate and silicate glasses: Stress-corrosion susceptibility and hydrolytic resistance

Journal of Non-Crystalline Solids 551 (2021) 120414

https://doi.org/10.1016/j.jnoncrysol.2020.120414

Abstract:

A double cantilever beam technique in air equipped with ultrasound modulation was used to measure the crack velocity v in borate and silicate glasses. In all glasses v and the stress intensity KI followed the empirical correlation v ~ KIn. Indicated by its smallest KI at v = 1 µm s − 1, KI* = 0.27 MPa m0.5, the silicoborate glass containing 70 mol% B2O3 was found most susceptible to stress-corrosion enhanced crack growth. Contrarily, the sodium calcium magnesium silicate glass appeared least susceptible with KI* = 0.57 MPa m0.5. No clear correlation is evident between KI*, reflecting the stress-corrosion susceptibility, and the hydrolytic resistance for all glasses under study, but values of n obtained from the present study and taken from previous literature for 35 glasses tend to decrease with increasing network modifier ion fraction. Energy dissipation during stress-corrosion enhanced crack propagation is assumed to cause this trend.

N. Romero Sarcos, D. Hart, H. Bornhöft, A. Ehrenberg, J. Deubener

Rejuvenation of granulated blast furnace slag (GBS) glass by ball milling

Journal of Non-Crystalline Solids 556 (2021) 120557, ISSN 0022-3093

https://doi.org/10.1016/j.jnoncrysol.2020.120557

(http://www.sciencedirect.com/science/article/pii/S0022309320306670)

Abstract

Differential scanning calorimetry, thermogravimetry and gas analysis were used to study the impact of high-energy mechanical milling (HEMM) on the rejuvenation of a granulated blast furnace slag (GBS). It is found that milled GBS – ground granulated blast furnace slag (GGBS) in practice – shows an enormous release of exothermic heat in the sub-Tg range upon heating at 10 K min−1, which increases with milling time and exceeds more than three times that of the unmilled GBS. Heating of GGBS revealed that the energy release of HEMM-activated glasses occurs at considerably lower temperatures than observed for thermally excited glasses (hyperquenched fibers). The difference in the characteristic release temperatures is assigned to two different relaxation mechanisms. The former (HEMM), is due to relaxation of structural defects on the surface of the powder particles, whereas the latter (hyperquenched glass), comprises relaxation of the entire glass structure throughout the volume.

Keywords: Rejuvenation; Relaxation; High-energy mechanical milling (HEMM); Calcium aluminosilicate glass; Granulated blast furnace slag (GBS); Ground granulated blast furnace slag (GGBS); Differential scanning calorimetry (DSC)

A. Zandonà, G. Helsch, R. Al-Mukadam, J. Deubener

The effects of a Li2O excess on the crystallization sequence of lithium aluminosilicate glass powders

Journal of Non-Crystalline Solids, 561 (2021) 120748, ISSN 0022-3093,

https://doi.org/10.1016/j.jnoncrysol.2021.120748

(https://www.sciencedirect.com/science/article/pii/S0022309321001071)

Abstract

The surface crystallization of melt-quenched lithium aluminosilicate (LAS) glasses with SiO2-contents between 77 and 79 mol% was investigated by high-temperature X-ray diffractometry. Glasses possessing a ratio Li/Al > 1 underwent far earlier crystallization (starting from 750°C) than their stoichiometric counterparts, developing solely quartz solid solution (Qss) and keatite solid solution (Kss) crystals during a heat treatment up to 1200°C. In turn, samples with Li/Al = 1 devitrified only above 900°C and exhibited the transient formation of cristobalite, whose lattice constants hint at a slight Li+Al stuffing. The composition, structural parameters and critical inversion temperature Tc of the obtained Qss crystals were analyzed and compared with the available literature sources, reaffirming the established mutually linear dependence between these properties.

Keywords: Glass; Crystallization; Quartz solid solution; Lithium aluminosilicate; Quartz inversion

J. Deubener, J.W.P. Schmelzer

Abstract

Statistical Approach to Crystal Nucleation in Glass-Forming Liquids

Entropy 23 (2021) 246

https://doi.org/10.3390/e23020246

In this work, methods of description of crystal nucleation by using the statistical approach are analyzed. Findings from classical nucleation theory (CNT) for the average time of formation of the first supercritical nucleus are linked with experimental data on nucleation in glass-forming liquids stemming from repetitive cooling protocols both under isothermal and isochronal conditions. It is shown that statistical methods of lifetime analysis, frequently used in medicine, public health, and social and behavioral sciences, are applicable to crystal nucleation problems in glass-forming liquids and are very useful tools for their exploration. Identifying lifetime with the time to nucleate as a random variable in homogeneous and non-homogeneous Poisson processes, solutions for the nucleation rate under steady-state conditions are presented using the hazard rate and related parameters. This approach supplies us with a more detailed description of nucleation going beyond CNT. In particular, we show that cumulative hazard estimation enables one to derive the plotting positions for visually examining distributional model assumptions. As the crystallization of glass-forming melts can involve more than one type of nucleation processes, linear dependencies of the cumulative hazard function are used to facilitate assignment of lifetimes to each nucleation mechanism.

Keywords: nucleation; crystal growth; general theory of phase transitions; glasses; glass transition- J. Deubener

Viscosity of Glass-Forming Melts

In Encyclopedia of Glass Science, Technology, History, and Culture

Editor(s): Pascal Richet, Reinhard Conradt, Akira Takada, Joël Dyon

Section IV : Transport Properties, 2021, 431-451

https://doi.org/10.1002/9781118801017.ch4.1

Summary

This chapter shows the fundamental importance of viscosity to describe the fluid character of the synthetic and natural glass-forming melts relevant to industry and geosciences. The melt response to shear and normal stresses is in most cases defined by a constant ratio between stress and deformation rate. Only under extreme forming conditions and for heterogenic melts deviations from such a Newtonian viscosity are observed. On the atomistic scale, viscous flow is linked to the complexity of cooperative rearrangements of structural entities leading to a non-Arrhenian temperature dependence above T g. In the glass transition range, viscosity becomes time-dependent as the timescale of structural relaxation exceeds those of the deformation process. The increasing inequality leads to the isostructural viscosity of the unrelaxed melt state at temperatures far below T g. The various methods used to measure it over 14 orders of magnitude are described along with three-parameter equations used in practice to predict the viscosity?temperature dependence with high accuracy. Owing to their technical importance, the effect of oxide components on viscosity is discussed especially in relation to changes in the connectivity of rearranging structural units, which are most prominently seen by the viscosity hump of the boron anomaly. Whereas viscous flow is generally governed by the fractions of major components, trace amounts of water have an exclusive role in accelerating the network dynamics. In addition, viscosity is strongly effected by microstructure, when inclusions are present in the melt. In the case of crystal-bearing melts, a strong increase in viscosity with increasing crystal fraction becomes evident, while bubbles tend to decrease viscosity if sheared at high capillary numbers.

Keywords: glass transition; glass-forming melts; heterogeneous liquids; structural relaxation; viscosity measuring methods

J. Deubener, G. Helsch

Glasses for Solar-energy Technologies

In Encyclopedia of Glass Science, Technology, History, and Culture

Editor(s): Pascal Richet, Reinhard Conradt, Akira Takada, Joël Dyon

Section IX : Environmental and Other Issues, 2021, 1113-1123

https://doi.org/10.1002/9781118801017.ch9.4Summary

Glasses are well-established materials for solar energy with rapid payback times and the high environmental compatibility required for sustainable energy concepts. As reviewed in this chapter, glass is not only playing an important role as transparent cover and substrate in various conversion systems producing electricity, heat, and fuels from solar radiation but is also utilized to clean natural resources such as water and air through solar photocatalytic processes at its surfaces. Special attention is paid to the optical properties relevant to the transmission, redirection, and collection of solar energy in various conversion systems. Finally, a look is taken into the future, to the challenges facing glass in solar technologies that are emerging or have already become an integral part of the renewable energy sector during the last two decades.

Keywords: glasses; photovoltaic cells; solar electricity; solar fuels; solar heating devices; solar thermalpower plants; solar water treatments; solar-energy technologiesR. Al-Mukadam, I. Götz, M. Stolpe, J. Deubener

Viscosity of Metallic Glass-Forming Liquids Based on Zr by fast-Scanning Calorimetry.

https://doi.org/10.1016/j.actamat.2021.117370

Abstract

Fast-scanning calorimetry was applied to retrieve the viscosity of supercooled liquids of the Zr-based bulk metallic glasses (BMGs) Vitreloy 105 and AMZ4 for temperatures from standard glass transition down to ∼0.78Tg/T. Characteristic temperatures of the glass transition were translated into viscosity values by means of composition-independent shift factors based on the equivalency between structural relaxation and viscous flow. The extended MYEGA model with a fragile term dominant at high-temperatures and a strong term dominant at low-temperatures describes the entire viscous range. The analysis revealed that Vitreloy 105 and AMZ4 are strong liquids for log10η ≥ 4.9–5.5. In turn, the fragile-to-strong crossover is centred on 0.69Tg/T for Vitreloy 105 and on 0.66Tg/T for AMZ4. The extent of the fragile-to-strong transition was found to be larger for Vitreloy 105 than for AMZ4, while their values agreed well with the inverse relation between transition factor and kinetic fragility of the strong regime established for BMG-forming liquids.

Keywords: BMG, Vitreloy 105, AMZ4, Viscosity, Fragility, Fragile-to-strong crossover, Fast-scanning calorimetryBornhöft, H., A. Zellmann, J. Deubener

Kinetics of the adherence layer formation of direct white enamel on sheet steel with deposited nickel layer

Email – Mitteilungen des Deutschen Emailverbandes e.V. 69 (2021) 40-51Abstract